Cooling systems are critical for large plants, power stations, and refineries for improving operational efficiency. They control temperature, improve processes, and protect efficiency. However, these systems can harbor dangerous bacteria, the most concerning being Legionella.

Legionella is more than just another waterborne microorganism. It is the bacterium that causes Legionnaires’ disease, a potentially lethal form of pneumonia. In industrial environments, where cooling towers and evaporative condensers are prevalent, the threat is even greater. Understanding Legionella’s development, dissemination, and management is crucial for safety and regulatory purposes.

Legionella pneumophila is a type of bacterium found in soil and freshwater environments, like lakes and rivers. In small amounts, it is benign. Problems arise when it enters industrial water systems, such as heating systems, cooling towers, or even ornamental ponds, where it can thrive and reach dangerous levels.

Legionella can cause a lung infection called Legionnaires’ disease if it is inhaled as small water droplets or mist. In addition, the bacteria have a minor variant known as Pontiac fever, which only causes flu-like symptoms. So, part of the industrial facilities’ duties is to make sure that bacteria do not multiply in their cooling systems.

Industrial cooling systems often provide ideal conditions for Legionella growth — warm water, stagnant areas, and nutrients from dirt, scale, or organic matter.

Key factors that cause its growth include:

The main danger from Legionella comes from inhalation, not drinking water. Cooling towers discharge water vapor and fine droplets into the air as part of their regular operation. If these droplets contain Legionella, they can travel over long distances before being inhaled by people nearby.

Industrial sites located near offices, residential areas, or public spaces can unknowingly expose many people to risk. Outbreaks have been traced back to a single poorly maintained cooling tower, sometimes infecting dozens in a short time.

Legionnaires’ disease is a serious ailment due to its health complications. The disease is known to have a 10% mortality rate. The most susceptible populations include older people, smokers, and people with weakened immune systems.

With regards to legal matters, not managing Legionella can result in significant financial penalties, shutdown orders, and, in severe situations, even imprisonment. Numerous countries have regulations around managing industrial cooling systems. Compliance is not only to avoid legal consequences, but to ensure the safety of employees, the public, and the surrounding areas.

Facility managers have been using biocides such as chlorine, bromine, or isothiazolinones for the last fifty years to chemically kill Legionella bacteria through the cooling systems of the industry. These chemicals do kill bacteria, and chemical deposits in pipes are avoided.

Even though these methods do their job, they still entail strict scheduling, continuous monitoring, and careful dosing. A relapse in the treatment can result in Legionella coming back.

In recent years, the water treatment industry has evolved due to emerging technologies. Current technologies pay special attention to monitoring, automated systems that mitigate human error, and the use of safer chemicals.

Some of the most effective approaches include:

Modern water treatment technologies use automation for tracking water quality parameters, including temperature, pH, and oxidant levels. Advanced warning systems notify operators of legionella concentration and risk conditions to ensure optimal response.

These utilize mixtures of ozone, hydrogen peroxide, and ultraviolet light to generate highly reactive radicals that destroy biofilm, bacteria, and organic matter. As compared to heavy chemical dosing, AOPs are more environmentally friendly.

Warm water at a temperature of 20-45°C provides a suitable environment for Legionella to thrive and multiply. Hence, maintaining the cold water temperature below 20 degrees Celsius and the hot water above 50°C in an industrial setting can effectively inhibit the growth of Legionella.

Legionella grows on the sticky layer, also known as biofilm, developed on the surfaces in water systems. When biofilms are controlled using advanced technologies or chemicals like antimicrobials and enzymes, it exposes legionella and makes it easy to kill them.

With cloud management systems, a facility manager can remotely monitor and manage the industrial cooling systems. Real-time performance metrics, alarms, and treatment logs are all readily accessible.

Legionella control is not a ‘fix it once’ problem. It requires ongoing attention and investment. A proactive approach saves money in the long term by avoiding shutdowns, reputational damage, and legal trouble.

Modern water treatment providers can tailor solutions to the specific needs of industrial cooling systems. It means fewer risks, better compliance, and safer operations.

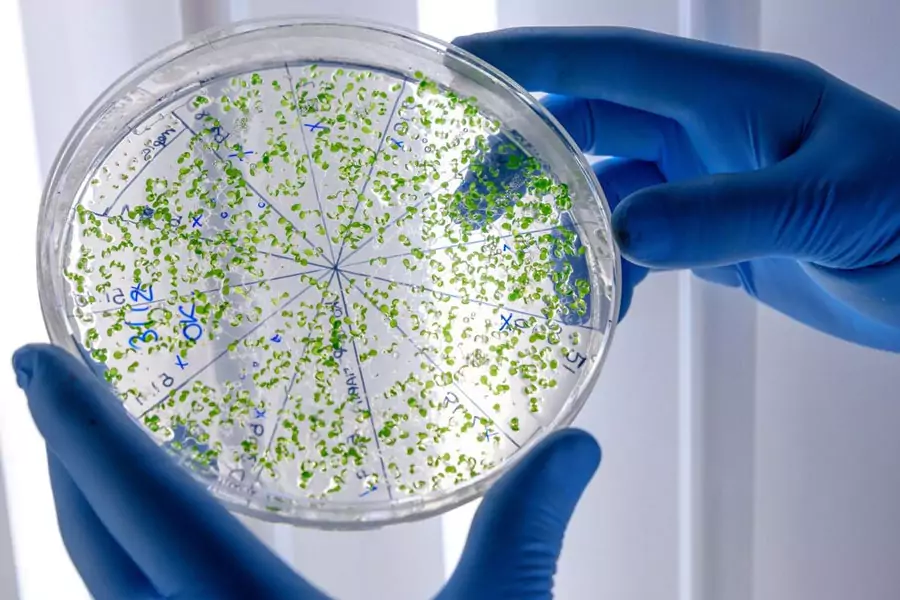

Our rapid microbial testing product can help you screen water regularly and take proactive steps to contain and eliminate them. Using our microbial testing product and ultrasonic scale prevention will help you check the water early and prevent scale formation in cooling towers.

Industrial cooling systems are essential for modern industry, but they must be managed with care. Legionella is invisible until it strikes, and by then, the damage may already be done. By combining proven treatment methods with advanced technology, facilities can protect people, stay compliant, and keep operations running without interruption. Consult our experts to get advanced microbial testing, water disinfection, and ultrasonic scale prevention products.

Puroxi Pure Water Global Inc was shortlisted for the awards category, Water Solutions Provider of the Year! As highlighted, it was some good news. I can confirm you that you have been chosen as the 2023/24 winners. Congratulations Zak! The generic winner’s logo has been attached which you can utilize to promote the recognition and the official press release will be conducted in March (defined date to come

Contact Us